Automatic Unloading

2019-04-25Gantry Robot

2019-04-27

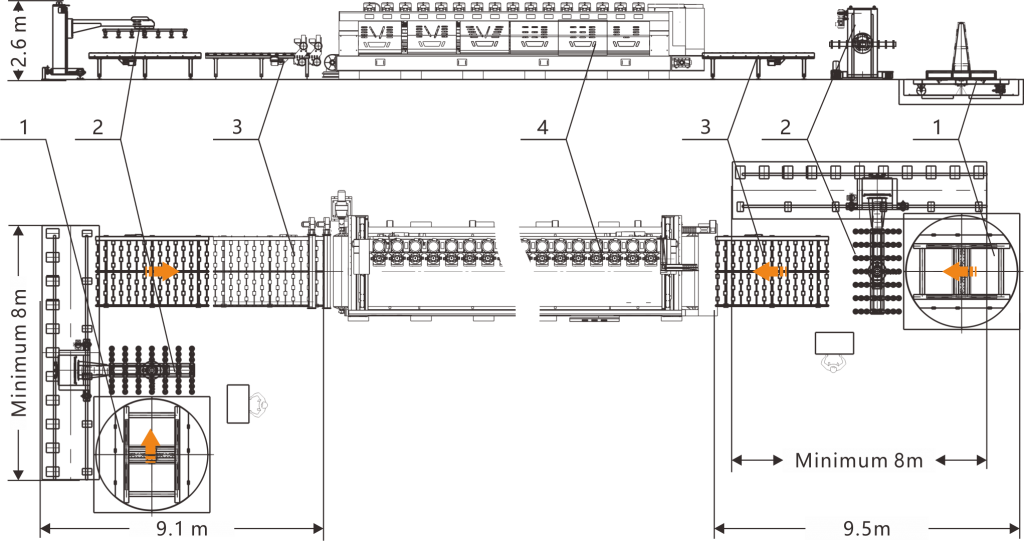

- Cantilever Robot is a robot whose job is to load and unload slabs on virtually any stone processing

- line or machine (including resin lines, quartz plants, polishing lines, and CNC machines).

- It can communicate in any language and receives orders through a user-friendly touch screen

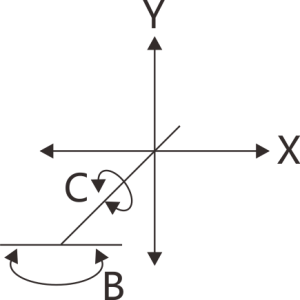

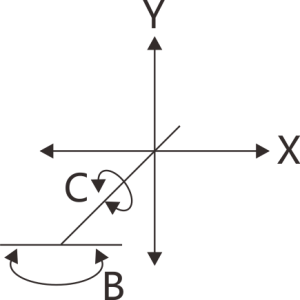

- (Schneider Electric PLC). Its four axes (X, Y, B, C) are controlled by encoders and inverters in order

- to ensure precise, smooth and fast movements (cycle time for 8-meter long X rails is around 1 minute).

- It can handle a wide range of materials (including marble, granite, and quartz slabs) even if they are

- cracked or contain holes. This is possible thanks to the use of safety, non-return valves, and sensors for reading minimum vacuum levels. In other words, the robot can handle situations in which up to five suction cups fail due to face cracks or holes in the slabs.

- It is smart. By means of weighing cells, it can detect if there are two or more wet slabs stuck together in order to avoid slab dropping. Additionally, in the event of a power failure, it can implement a safety system to maintain effective vacuum levels. With the help of a turn-over table, it can also perform "book-matching" operations.

- The cantilever design and various other manufacturing details make it a reliable and flexible assistant that can be installed in many different configurations so as to optimize operations and material flow. Compared to traditional human-handling by means of cranes, it has proved to be safer and more efficient, ergonomic and cost-effective.

- It payback period varies depending on the country where it operates, but considering its outstanding performance/price ratio, it is always a good investment.