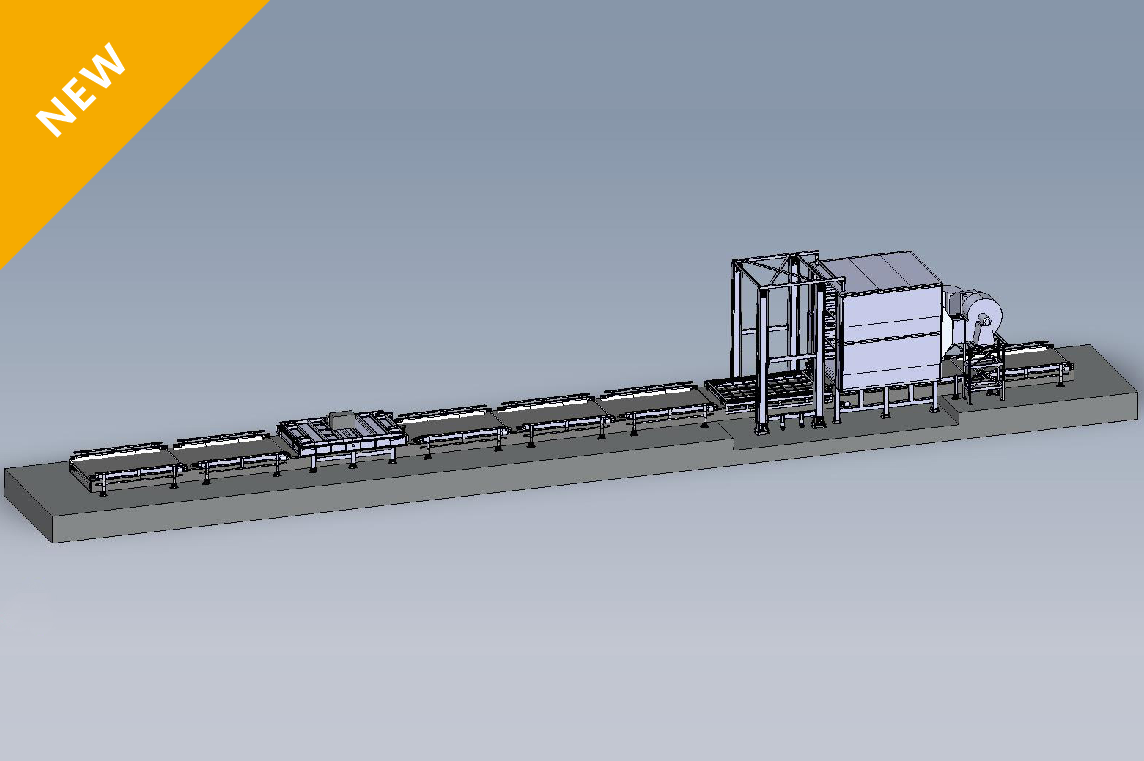

It can be installed in different sections of the line and can really be considered the “heart” of any resin line. It has 45 layers and, depending on the resin line configuration, it can perform both drying (20 layers) and hardening (25 layers) tasks, or only hardening (45 layers). The concept design is simple and efficient: a lift takes the slab from the conveyor, places it on the assigned layer and, after catalysis, retrieves it in order to send it to the next phase. The fully automatic operations are managed by the Programmable Logic Card (PLC).

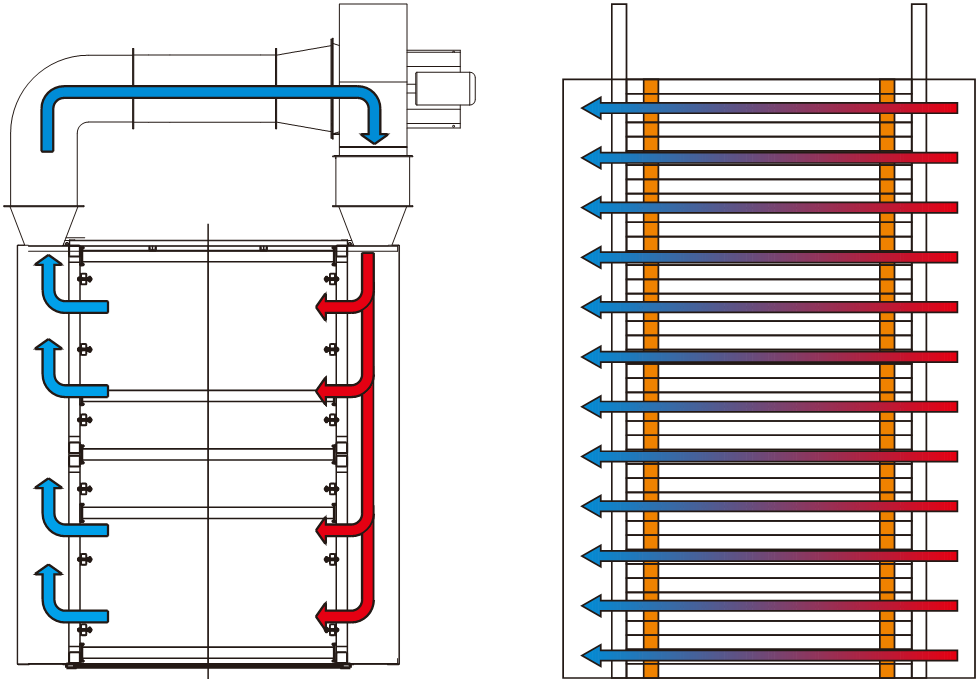

It is designed to assure uniform temperatures on the slab surface. Sensors detect humidity and temperature, in order to properly control the air flow in the chamber. This is to guarantee proper conditions for the correct catalysis of the resin. Drying and hardening tasks are performed at 45°C to 60°C and can take from 60 to 90 min.